Insisting on Excellence

Aero Gear has developed a reputation for excellent quality, strong gear expertise and the application of lean philosophy in our manufacturing processes.

Our Facilities

Located in Windsor, Connecticut, our 100,000 sq. ft of climate-controlled manufacturing space includes specialized equipment for the aerospace gear industry such as low-pressure vacuum carburizing, precision grinding, rotor balancing, isotropic superfinishing, non-destructive testing, a metallurgical laboratory, and full CMM capability. This vertical integration enables us to offer significantly shorter lead times, excellent quality control, with greater efficiencies and improved customer service.

Gear Type/Size Capability

| Type of Gear | Pitch Diameter | Diametral Pitch | Face Width | Unground Tooth | Ground Tooth |

|---|---|---|---|---|---|

| Spiral Bevel Gear | 16 inches | 3 to 40 DP | 3.5 inches | AGMA Class 11 | AGMA Class 14 |

| Zerol Bevel Gear | 12 inches | 3 to 40 DP | 2.5 inches | AGMA Class 11 | AGMA Class 13 |

| Straight Bevel Gear | 20 inches | 3 to 48 DP | 3.0 inches | AGMA Class 10 | Not Applicable |

| External Spur Gear | 18 inches | 3 to 48 DP | 8.0 inches | AGMA Class 10 | AGMA Class 14 |

| Internal Spur Gear | 20 inches | 3 to 48 DP | 8.0 inches | AGMA Class 10 | AGMA Class 14 |

| External Helical Gear | 14 inches | 5 to 48 DP | 8.0 inches | AGMA Class 10 | AGMA Class 13 |

| Internal Helical Gear | 14 inches | 6 to 48 DP | 4.0 inches | AGMA Class 10 | AGMA Class 13 |

| Involute Spline | 18 inches | 3/6 to 80/160 DP | 8.0 inches | ANSIB92.1 Class 5 | ANSIB92.1 Class 5 |

Our Capabilities

Our capabilities span numerous disciplines in the gear industry. We believe keeping our manufacturing, design, and testing under one roof leads to higher consistency, and shorter lead times.

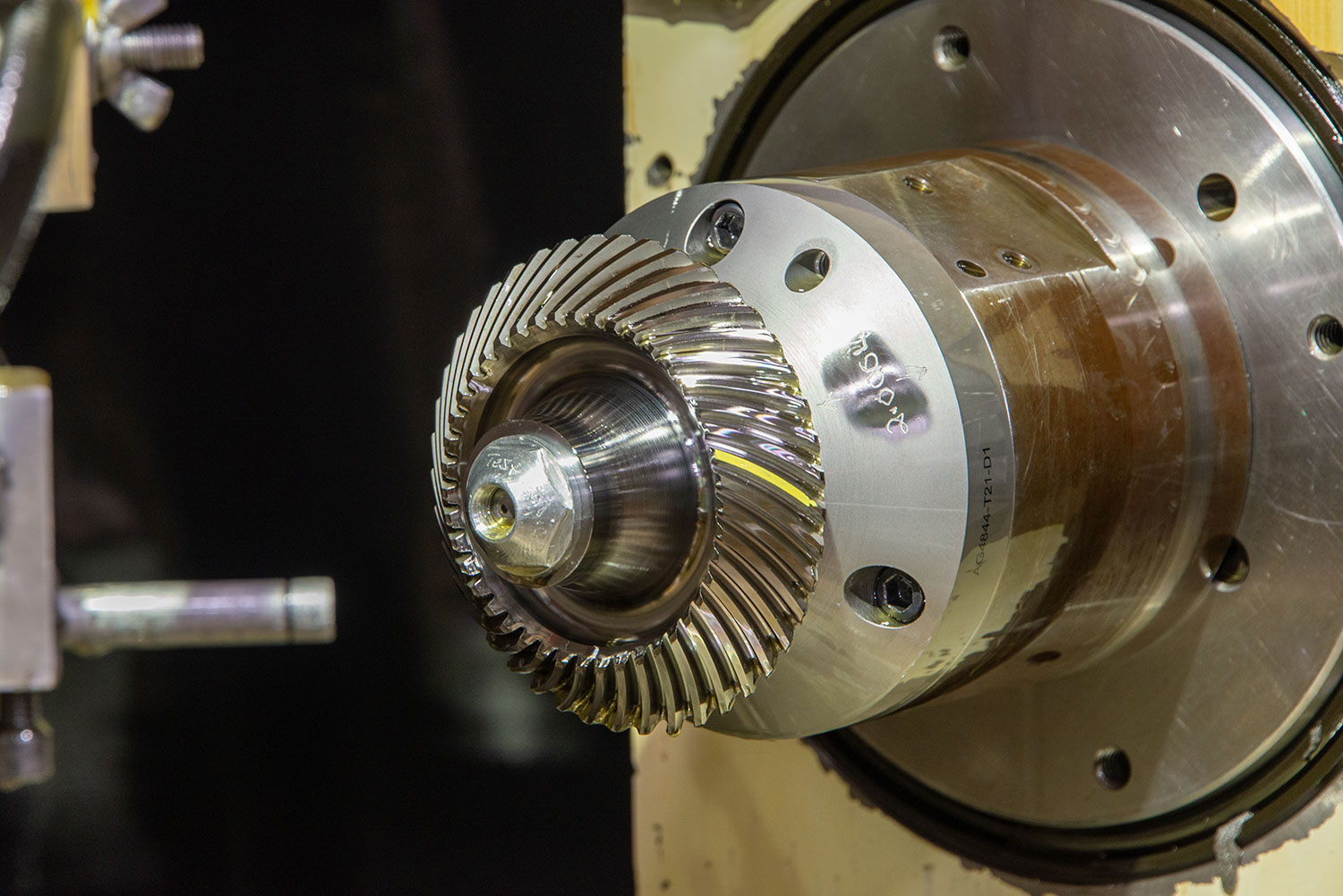

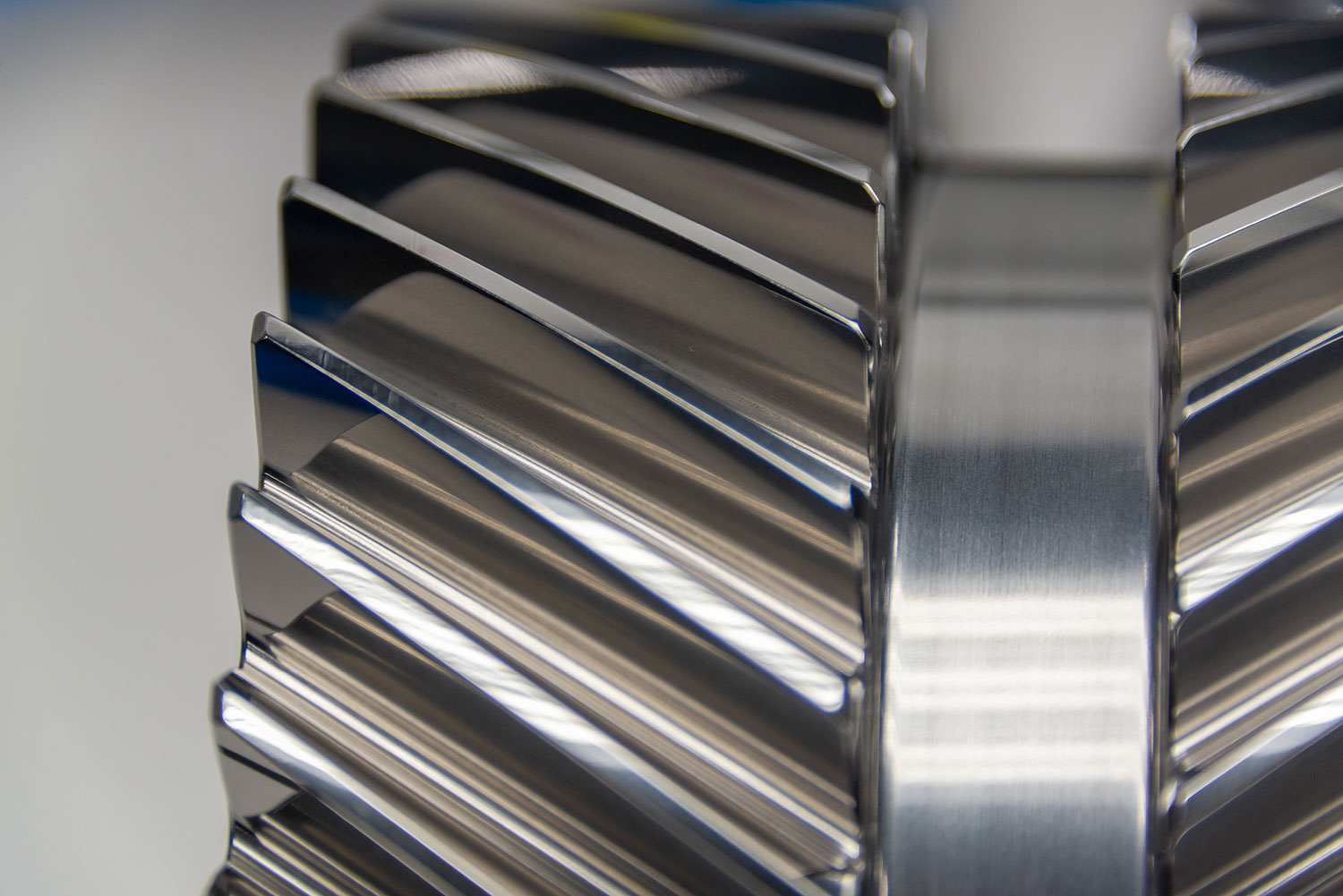

Parallel Axis Gears

Internal and external, spur and helical precision grinding

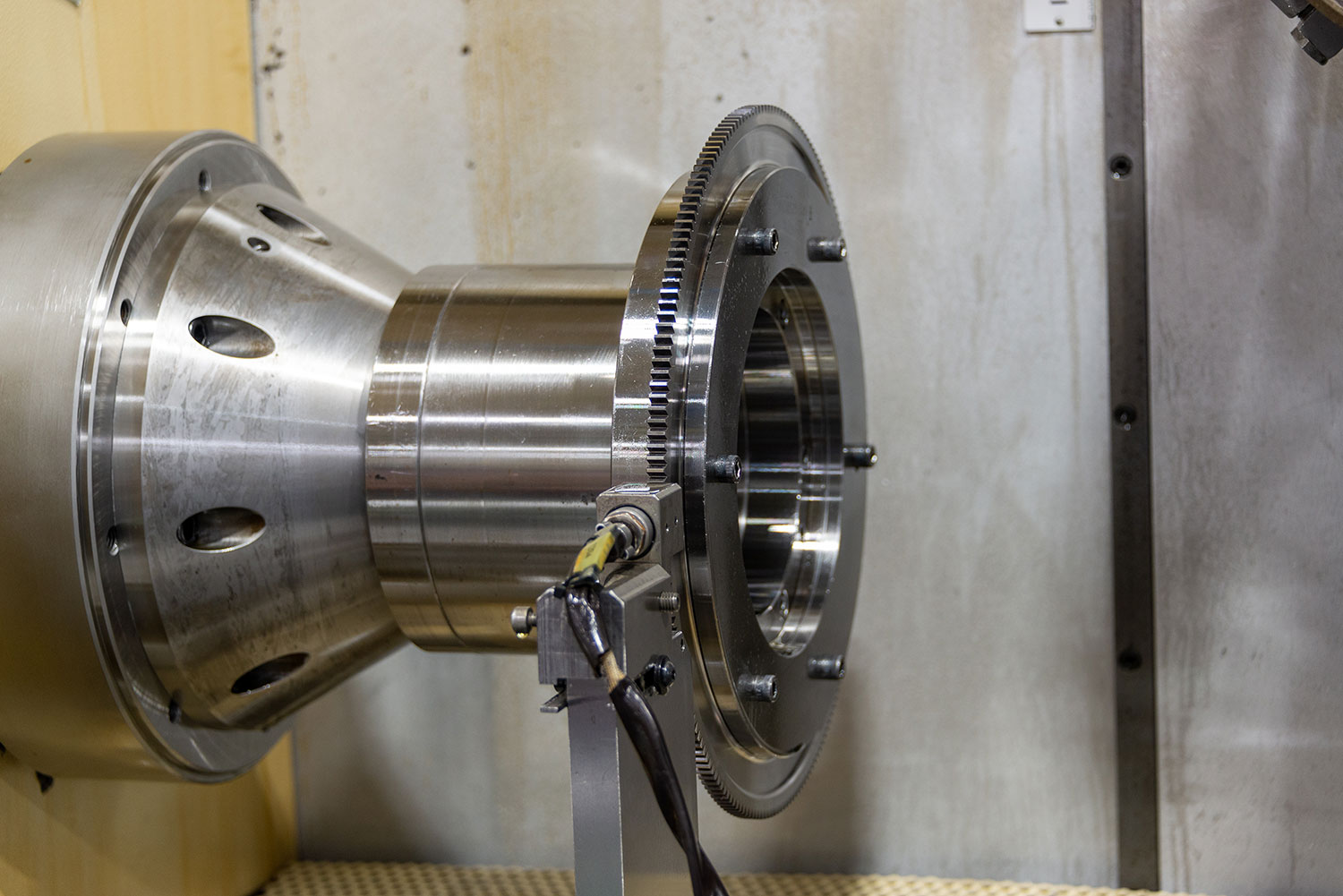

Spiral Bevel Gears

Expertise in manufacturing and design of Spiral Bevel gears

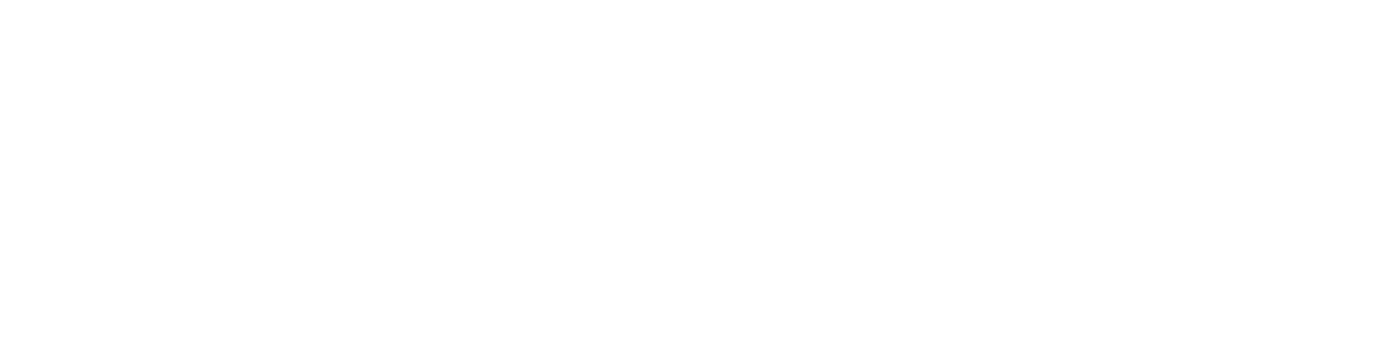

Cylindrical Grinding

Precision cylindrical grinding of external diameters, internal diameters, integral bearing raceways, and tapers to within 50 millionths of an inch and as low as 3 µin (0.076µm) Ra

MCM

5-axis milling capabilities for large aluminum and magnesium gearboxes up to 51 inches (1300mm) in size

Gearbox Assembly

Adaptable gearbox assembly area allowing assembly of multiple, simultaneous accessory or power drive transmission systems

Gearbox Testing

Complete suite of functional gearbox testing

Low Pressure Vacuum Carburizing

Low Pressure Vacuum Carburizing of gear steels such as AISI 9310, Pyrowear 53, Pyrowear 675, M50 NiL, Ferrium C61, and Ferrium C64

Quenching

State-of-the-art quenching capabilities utilizing computational fluid dynamics analyses to predict and limit heat treat distortion

Metallurgical Lab

Fully equipped In-House metallurgical testing

Isotropic Superfinishing

Isotropic superfinishing of parallel-axis and bevel gears as low as 1 µin (0.025µm) Ra

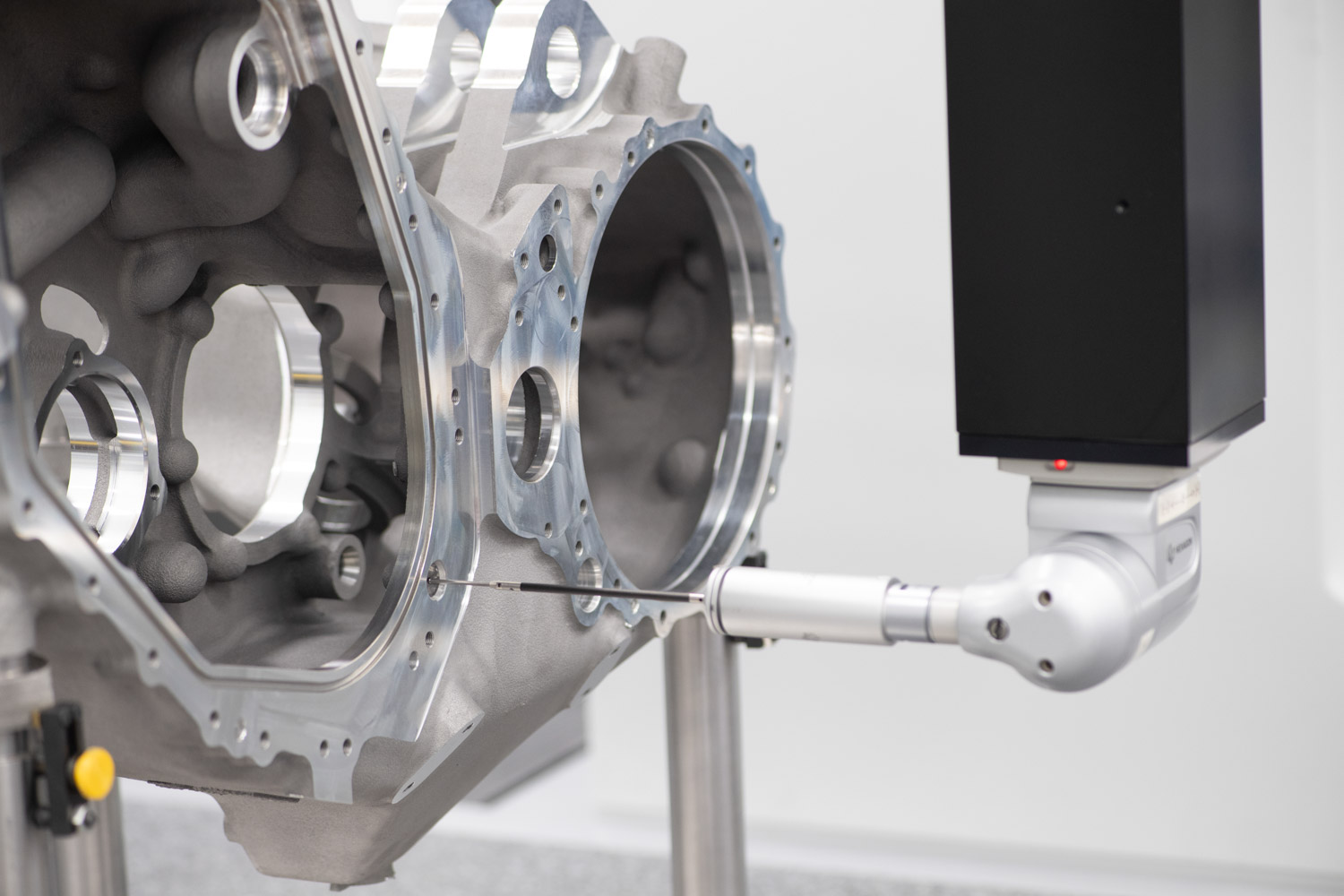

CMM

CMMs and gear inspection equipment, accurate and repeatable within 1µm on up to 54” (1372mm) parts