QUALITY:

certifications, cmm inspection

Nothing is more important to us than the quality of the products we produce and the service we provide. The evidence is in the expertise of our inspection technicians, the capital investment in state of the art equipment (including CMM and MM), as well as our processes of Continuous Improvement and Kaizen events.

We are committed to comply with all requirements and continually improve the quality and flow of our product through teamwork, cooperation and development of our people. Aero Gear’s QMS is AS9100 Rev D and ISO 9001:2015 certified. NADCAP certified for Heat Treating, Surface Temper Etching and Magnetic Particle Inspection.

Equally important is the status we have with our customers, and we have a comprehensive list of customer certifications, including UTC Supplier Gold status and achieving Sikorsky Top Supplier.

CERTIFICATIONS

In addition to customer and third party standards, Aero Gear’s QMS is AS9100 Rev D and ISO 9001:2015 certified. NADCAP certified for Heat Treating, Surface Temper Etching and Magnetic Particle Inspection.

. NADCAP certified for Heat Treating, Surface Temper Etching and Magnetic Particle Inspection.

REGULATORY AGENCY CERTIFICATIONS

NADCAP: Heat Treating . Chemical Processing . Non Destructive Testing

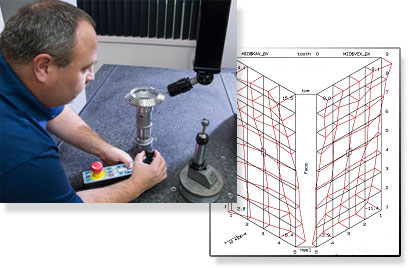

CMM INSPECTION

Gears and gearbox assemblies are carefully inspected with the latest metrology equipment and by staff experienced in gear development.